Fin-Diemme provides complete turnkey solutions tailored to fit your exact requirements. We design and construct all of the components required to provide the complete line which ensures you have a single point of repsonsibility and a fully integrated system.

Hot-melt adhesive application via high speed roller coater onto food trays inbetween the thermoformer and cutting station. Trays are formed with mono PET to make the tray recycleable.

Hot-melt adhesive application via high speed roller coater onto food trays in line with the thermoformer, Form with mono PET to make the tray recycleable.

Complete system for the preparation and insertion of absorbant pads into food trays

Hot melt roller coating system with a fixed bed for the material being coated allowing it to be held during the coating process.

Fin-Diemme combine two component adhesive and automation experience to produce turnkey solutions for in line gasket application.

Fin-Diemme manufacture complete coil to coil coating systems for hotmelt adhesive systems.

Compact systems for high ouput application of water based adhesives such as PVA, EVA, Phenolics and Polyurethanes.

Fin-Diemme produce a wide variety of panel lamination techniques including bead application for one and two component polyurethanes which may have fast cure speed.

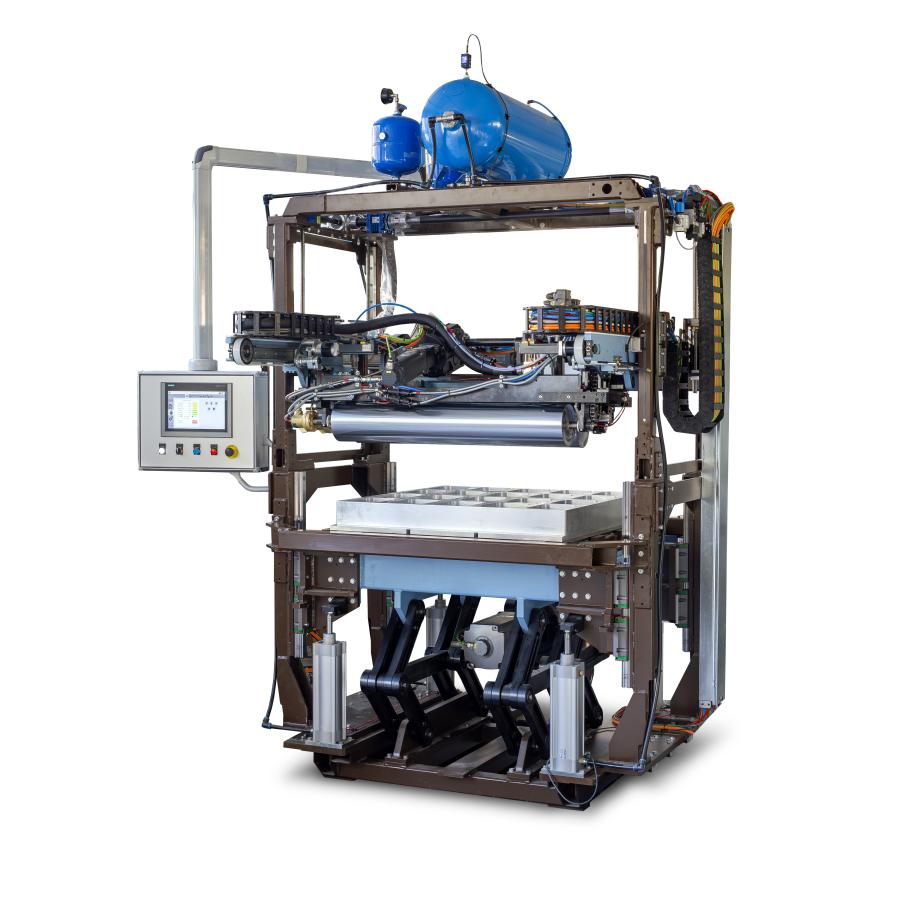

Fin-Diemme provide the complete solution to meet your liquid injection molding needs incoportating the precision dosing of the materials together with heated molds.

Fin-Diemme has developed a wide range of headlamp market sector assembly stations include complete glue cells, hollow bolt assembly and measurements, photometry and test stations.

Fin-Diemme manufacture complete coil to coil laminating and coating systems for liquid and hotmelt adhesive systems.

The Fin-Diemme range includes a wide variety of solutions for the flat laminating of sandwich panels using hotmelt technology.