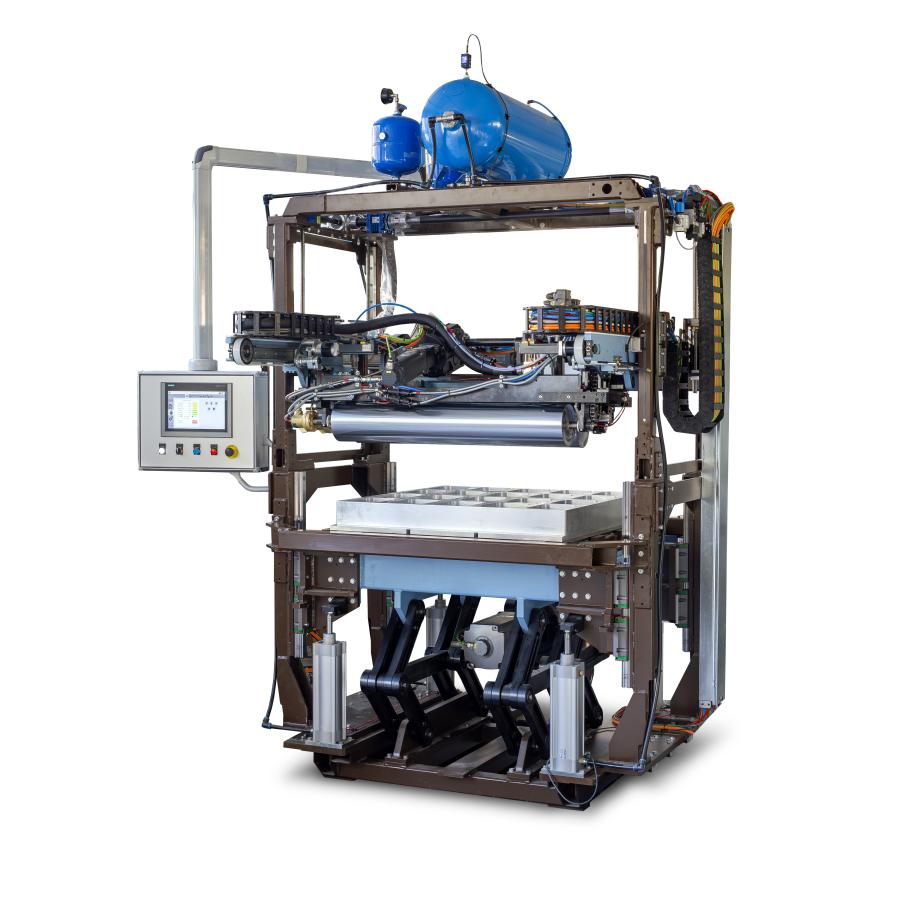

Fin-Diemme's Mid-Line Adhesive Coating system uses a unique bi directional heated roller coater for high speed cycle speeds combined with virtual cam technology to control the roller speeds and automation movement to place the trays in a supporting tool during the coating process and to transport the coating head over the trays to be coated. All the automation arrives as one single module to be fixed inbetween an existing thermoforming station and separate cutting station. Adhesive is automatically fed into the rollers via a tank melter. The rollers are easy change for varying material widths. By replacing standard PET-PE films with mono PET and applying adhesive just to the tray rims the trays are no longer single use and can be completely recycled to produced PET products.