Having developed a global reputation for the supply of reliable, durable and affordable dosing systems for the application of one and two component adhesives in the high volume high demand automotive market, Fin-Diemme has continued to expand the technologies supplied into this market sector both in adhesive application and in high technology equipment to meet the needs of the customer.

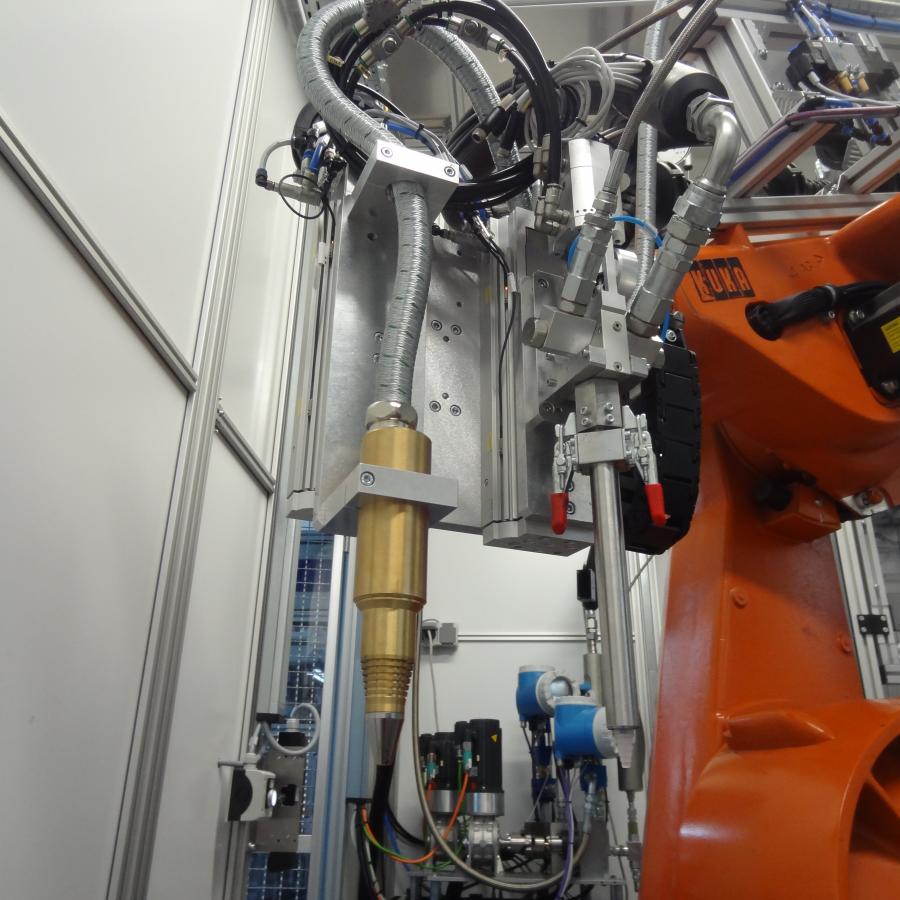

Precision dosing of 2 component Polyurethanes, Silicones or hot applied Polyurethanes and Butyls to bond the headlamp lens and housing together at the end of the headlamp assembly. Fin-Diemme can supply the dosing system as unit or fully integetrate into a automatic glue station consisting of Plasma treatment and glue dosing via Robot togeher with material handling such rotating tables, servo press and interchangeable fixtures. The adhesive application systems consist of single or tandem transfer systems for high or low viscosity products and precision gear dosing for flow and ratio control.

The application of adhesives onto various materials such as PVC, leather, carpet, foams, paper honeycomb and PU leatherette for automotive internal components such as armrests, dashboards, parcel shelves and door trims. The adhesive application systems include slot head, roller coaters, gravure roller and can be various adhesive technology, hot or cold applied. The material can be coated in a continuous roll to roll process or on smaller pre cut parts. Fin-Diemme provide a complete solution including all handling equipment, unwinds, rewinds, presses, accumulators, drying and transfer systems.